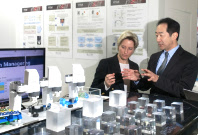

Baden-Wurttemberg Minister of Economy visited our exhibition booth at CeBIT2017.

Baden-Wurttemberg Minister of Economy, Dr. Nicole Hoffmeister-Kraut, visited our exhibition booth at CeBIT2017 on March 22, 2017. Minister of Economy took time from one’s busy schedule to visited only two companies in the Japan Pavilion,including our company.In addition to explaining our Cyber-Physical Production System (CPS), we introduced the collaborative activities of each research organization in Baden-Württemberg, including Fraunhofer Institute IPA and Karlsruhe Institute...